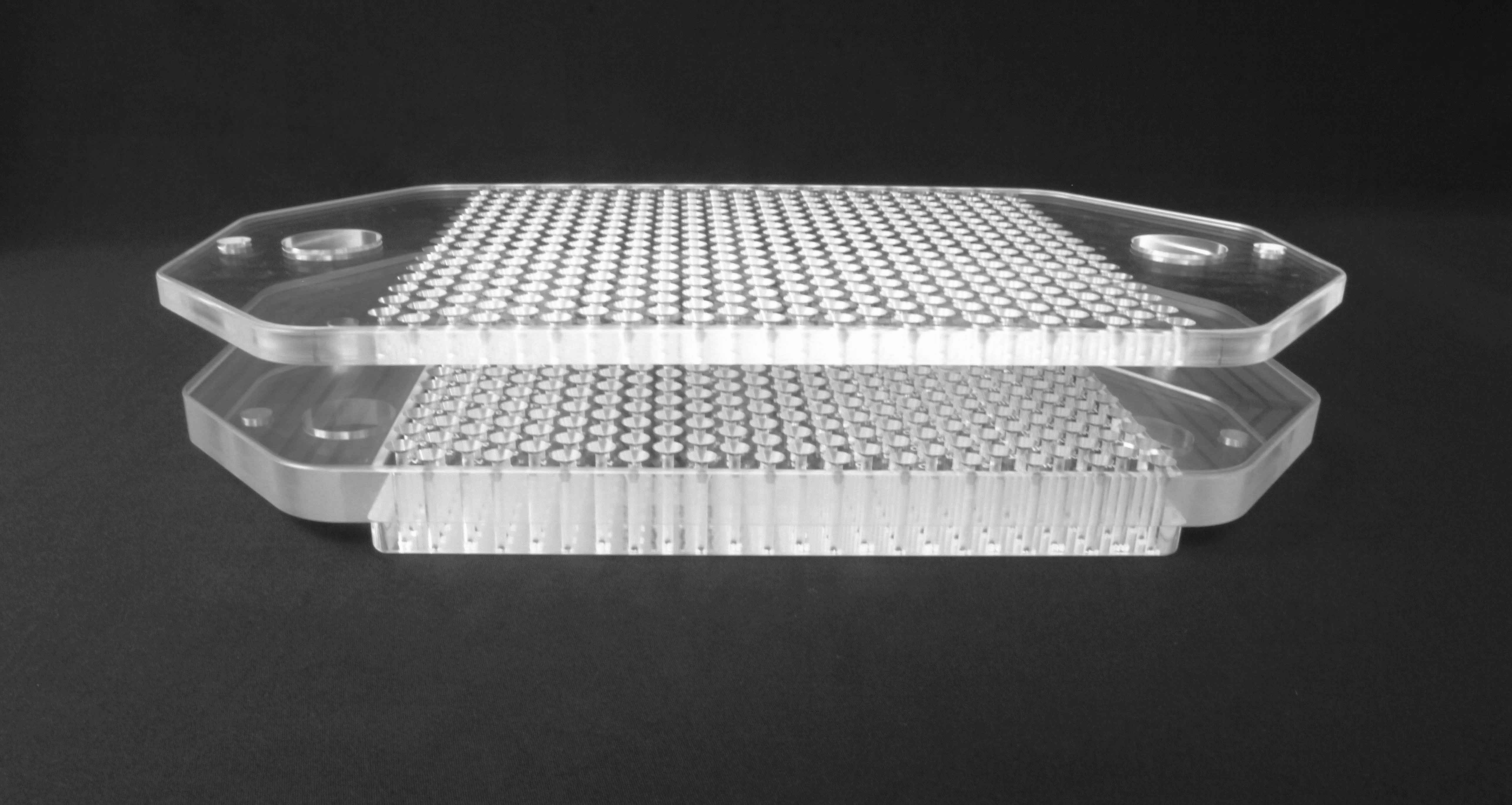

Needle Guides are mounted below the manifold that supports the needles running straight through the meat.

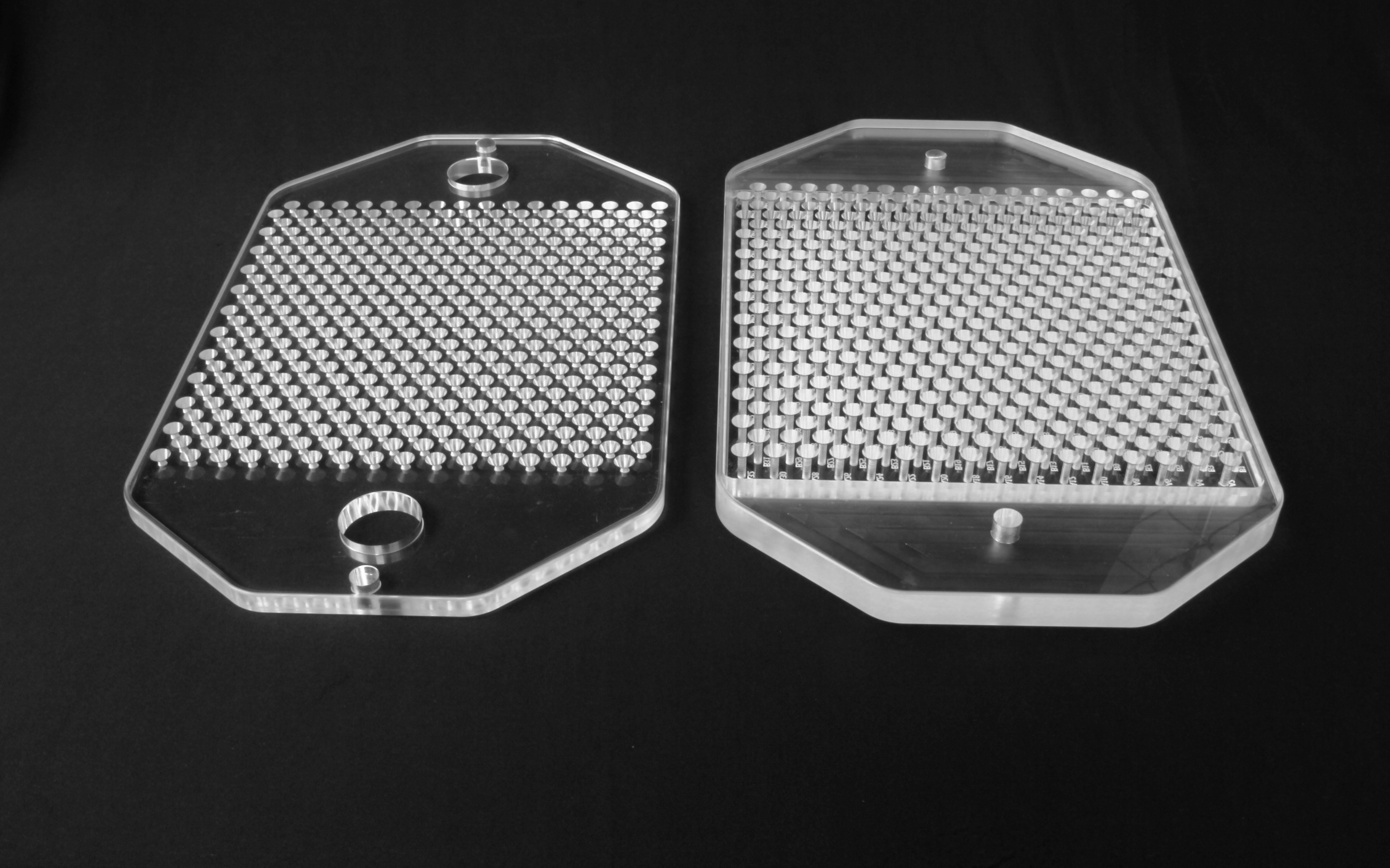

Needle Guides also interact with

a Multi-functional

system for the detection

of clogged needles enabling

individual

needle replacement.

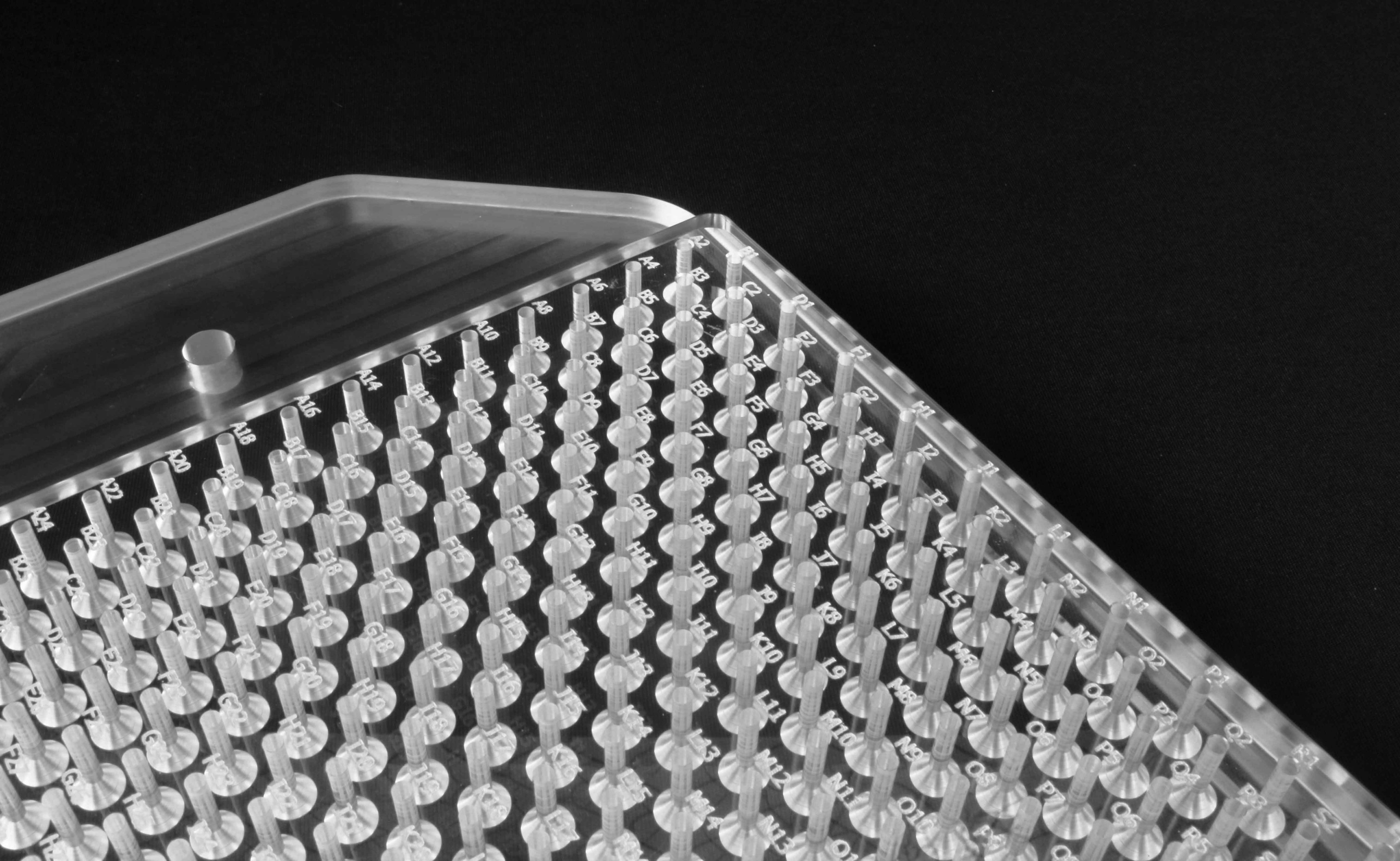

Each needle is numbered

at the bottom of the

needle guide

for systematic maintenance

and

needle replacement.

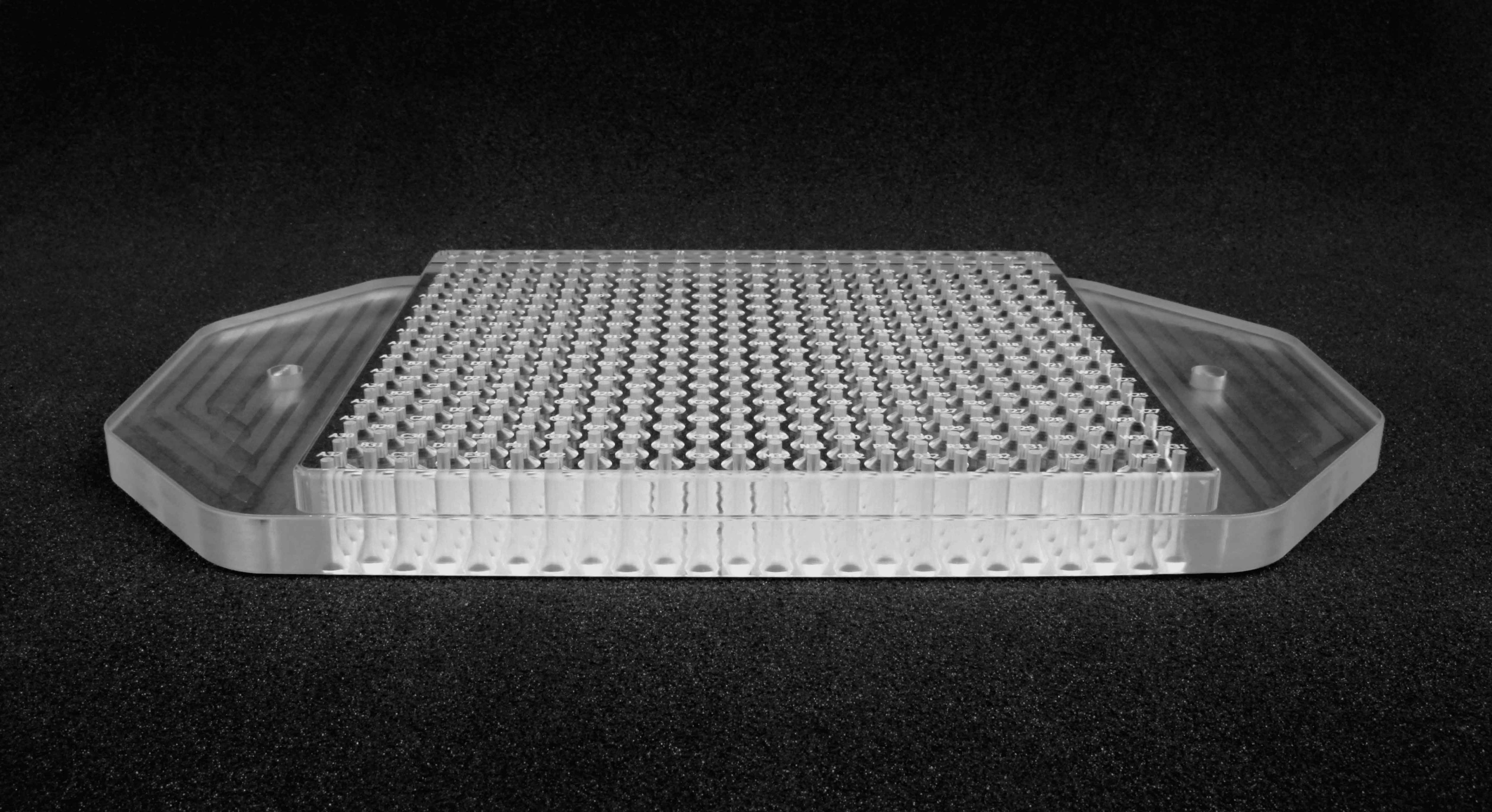

Needle Guides are

computer fabricated for precise spacing

of needles entering the fish. Polished surfaces and holes

to promote easy cleaning and sanitation.

The Needle Guides interface with a revolutionary DLC384 Clog Detector Device that identifies specific clogged needles in a 384 needle matrix for individual replacement.

Individual clogged needles can be identified

and marked for replacement in minutes.

It would take a layperson more than 8 hours

to check each needle also causing wear

and tear on

the needle hubs as well.

Find peace of mind in mass production with Tuna Technologies